İçindekiler

- Advancements in Customization

- Reduction in Time-to-Market

- Complex Geometries and Lightweight Designs

- On-Demand and Localized Production

- Material Innovations

- Supply Chain Resilience

- Environmental Sustainability

- Cost Savings in Tooling and Inventory

- Impact on the Labor Force

- Regulatory and Intellectual Property Implications

- FAQs (Frequently Asked Questions)

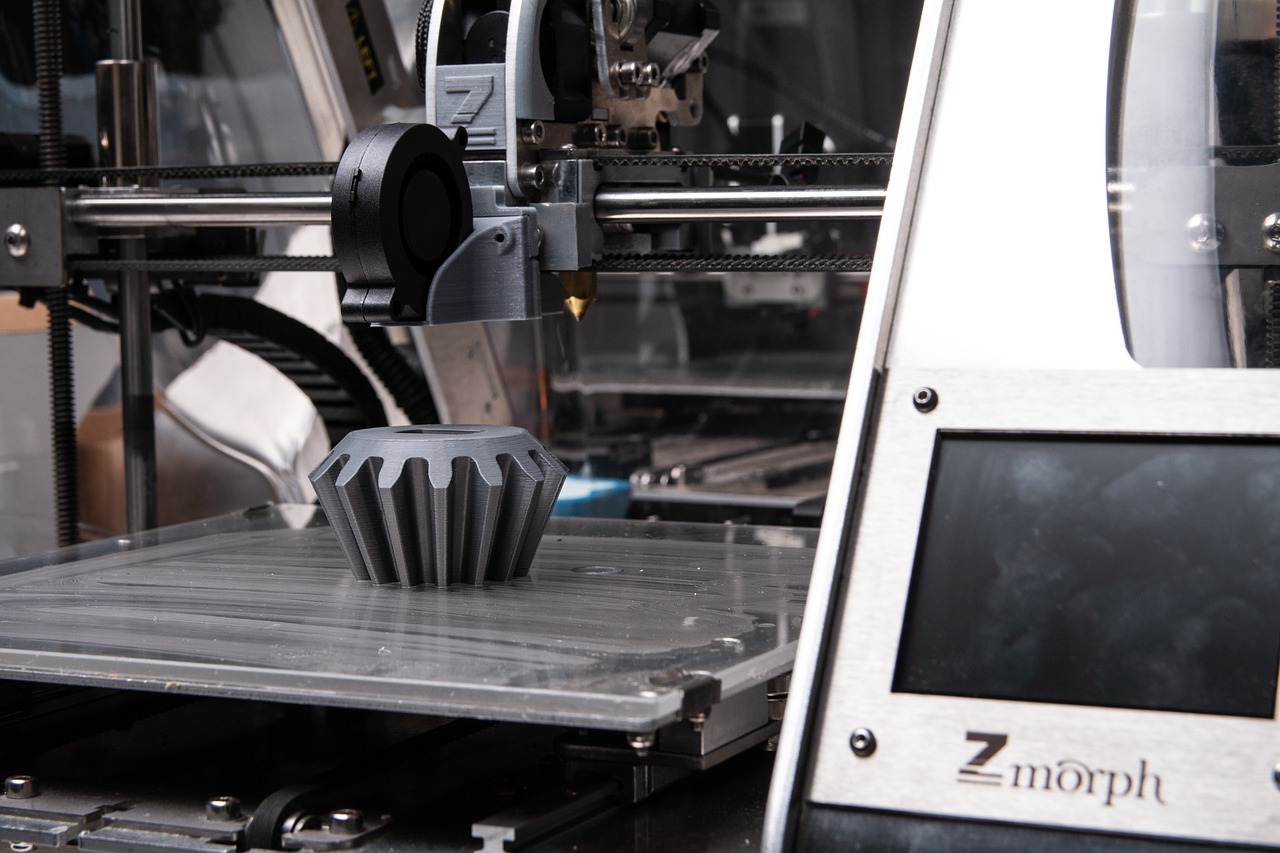

3D printing, also known as additive manufacturing, has been revolutionizing the manufacturing industry in recent years. This innovative technology allows for the creation of three-dimensional objects by layering materials such as plastic, metal, and ceramics based on a digital model. How 3D Printing is Changing Manufacturing is an important topic in today’s rapidly evolving industrial landscape, as it offers a wide range of benefits and opportunities for businesses and consumers alike.

One of the key aspects of how 3D printing is changing manufacturing is its ability to streamline the production process and reduce waste. Traditional manufacturing methods often involve subtractive processes, where material is cut away from a larger block to create the desired shape. This can result in a significant amount of waste material. With 3D printing, however, materials are added layer by layer, which minimizes waste and allows for more efficient use of resources.

Moreover, 3D printing enables the customization of products on a mass scale, opening up new possibilities for personalized and on-demand manufacturing. This means that companies can produce unique, tailor-made products for their customers without incurring the high costs typically associated with customization. Additionally, 3D printing has the potential to decentralize manufacturing by allowing products to be produced closer to the point of consumption, which can reduce transportation costs and lead times.

Furthermore, the use of 3D printing in manufacturing has implications for supply chain management, as it can reduce the need for large inventories and make it easier to adapt to changes in demand. This can lead to more agile and responsive production processes, ultimately benefiting both businesses and consumers.

As we delve deeper into the topic of How 3D Printing is Changing Manufacturing, we will explore the various industries and applications where 3D printing is making a significant impact. We will also discuss the challenges and future potential of this technology, providing a comprehensive overview of its role in the evolving manufacturing landscape. Join us as we uncover the exciting possibilities and implications of 3D printing for the future of manufacturing.

Advancements in Customization

3D printing has revolutionized the way products are customized. Traditional manufacturing processes often require expensive molds or tooling to create customized products, making it impractical for small-scale production. With 3D printing, customization is much more accessible and cost-effective. Companies can easily create unique, personalized products without the need for expensive tooling, allowing for greater flexibility in meeting the specific needs and preferences of customers.

Reduction in Time-to-Market

One of the significant ways 3D printing is changing manufacturing is by reducing the time it takes to bring a product to market. Traditional manufacturing methods can be time-consuming, especially when creating prototypes or small production runs. 3D printing allows for rapid prototyping and on-demand production, significantly shortening the time it takes to go from design to a finished product. This accelerated timeline gives companies a competitive edge by enabling them to quickly iterate on designs and respond to market demands more efficiently.

Complex Geometries and Lightweight Designs

Traditional manufacturing techniques often have limitations when it comes to creating complex geometries and lightweight designs. 3D printing, however, allows for the production of intricate and highly detailed structures that would be difficult or impossible to achieve using traditional methods. This capability has opened up new opportunities for innovation in various industries, such as aerospace, automotive, and healthcare, where lightweight yet strong components are crucial.

On-Demand and Localized Production

3D printing enables on-demand production, meaning items can be manufactured as and when they are needed, reducing the need for large inventories and warehouse space. Additionally, this technology has the potential to shift manufacturing closer to the point of consumption, leading to more localized production. This not only reduces transportation costs and emissions but also allows for a more agile and responsive supply chain.

Material Innovations

Advancements in 3D printing technologies have led to the development of a wide range of printable materials, including various plastics, metals, ceramics, and even biological materials. This expansion of printable materials has expanded the potential applications of 3D printing across diverse industries. For example, in the medical field, 3D printing is being used to create custom implants and prosthetics using biocompatible materials, leading to better patient outcomes.

Supply Chain Resilience

3D printing has the potential to enhance supply chain resilience by reducing dependencies on a single source of production. In traditional manufacturing, a disruption in the supply chain can have significant ripple effects. With 3D printing, companies can quickly pivot to producing components or products in-house, reducing the impact of supply chain disruptions caused by natural disasters, geopolitical events, or other unforeseen circumstances.

Environmental Sustainability

3D printing has the potential to contribute to environmental sustainability by minimizing material waste. Traditional subtractive manufacturing processes often result in a significant amount of waste material. In contrast, 3D printing is an additive manufacturing process, where material is deposited only where needed, reducing waste. Additionally, the localized production made possible by 3D printing can lead to a reduction in transportation-related emissions.

Cost Savings in Tooling and Inventory

Traditional manufacturing methods often require expensive tooling, molds, and inventory storage. 3D printing eliminates the need for many of these costly components. With 3D printing, products can be produced directly from digital designs, eliminating the need for tooling. Furthermore, on-demand production reduces the need for maintaining large inventories, leading to cost savings for companies.

Impact on the Labor Force

The widespread adoption of 3D printing in manufacturing has the potential to reshape the labor force. While it may reduce the demand for certain traditional manufacturing roles, it also creates opportunities for jobs related to 3D design, materials development, machine operation, and maintenance. As the technology continues to advance, the skill sets required in the manufacturing sector are likely to evolve, presenting both challenges and opportunities for the workforce.

Regulatory and Intellectual Property Implications

The rise of 3D printing introduces new challenges related to intellectual property rights and regulatory frameworks. The ability to easily replicate and distribute physical objects through 3D printing raises concerns about copyright infringement and product counterfeiting. As a result, there is a growing need to develop and adapt regulations to address these challenges and protect the rights of intellectual property owners while fostering innovation in 3D printing technology.

Conclusion: In conclusion, 3D printing is revolutionizing the manufacturing industry by offering a more efficient, cost-effective, and customizable production process. The technology has the potential to significantly impact various sectors, from aerospace and automotive to healthcare and consumer goods. As 3D printing continues to advance, it will become even more accessible to businesses and individuals, allowing for greater innovation and creativity in product development. This transformation in manufacturing processes is not only fascinating from a technological standpoint but also has practical implications for businesses and consumers alike.

Practical Applications: The knowledge gained from understanding how 3D printing is changing manufacturing can be applied in various ways in our daily lives. For businesses, integrating 3D printing technology into their production processes can lead to faster prototyping, reduced lead times, and more customized products. For consumers, it means the potential for personalized and on-demand products, from custom-fit clothing and shoes to personalized medical devices. As the technology becomes more widespread, we may see local 3D printing services offering on-demand manufacturing for a wide range of products, reducing waste and transportation emissions.

FAQs (Frequently Asked Questions)

Q: What materials can be used in 3D printing?

A: 3D printing can use a wide range of materials, including plastics, metals, ceramics, and even food-grade materials. The specific material used depends on the type of 3D printing technology and the requirements of the end product.

Q: Is 3D printing only for manufacturing complex parts?

A: While 3D printing is often used for creating complex geometries that are difficult or impossible to produce with traditional manufacturing methods, it can also be used for creating simple parts, tools, and consumer products.

Q: How affordable is 3D printing for small businesses or individuals?

A: The cost of 3D printing has been decreasing, making it more accessible for small businesses and individuals. Entry-level 3D printers are now available at relatively affordable prices, and there are also online 3D printing services that offer cost-effective options for printing on demand.

We’d love to hear from you! Share your thoughts on how 3D printing is changing manufacturing and any experiences you have with this technology. Join the conversation below!

Leave a Reply